menu Close

Manufacturing Circuit Board Mounting and Manufacturing Contracts

Circuit Board Mounting

High-level quality control and flexible support from mounting to assembly

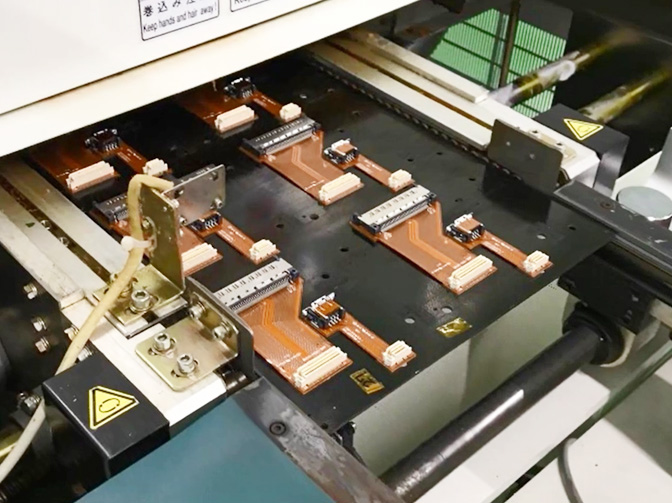

SMT and press fitting (connector press-fit mounting for circuit boards) support are available. Providing flexible support to meet customer needs ranging from general specifications to small lots and items requiring specialized jig tooling and customization.

In addition, we provide support on the design front such as procurement of specified components and selection of recommended parts based on the parts lists we receive from customers.

Handling for Urgent Plant Expansion Needs

When needs exceed the capacity of your company facilities or opportunity loss and other problems seem likely to occur due to insufficient resources, we hope you will consider us as your second factory and use our circuit board mounting services.

We have prepared an N2 reflow and a production line which can handle large size circuit board mounting in order to handle a wide range of customer requests.

In addition, we produce environmentally-friendly lead-free products inside booths with controlled temperature and humidity.

Operators with specialized knowledge manage the finish quality of products and inspection and verification are performed using testing machinery, ensuring all delivered products are high quality.

One-stop Shop for Support from Mounting to Assembly

Post-process after mounting such as the assembly of various modules can also be carried out by workers in clean booths free of any contamination. While maintaining traceability for key parts, we also provide services such as inspection operations.

Manufacturing Contracts

Providing stable services through a

variety of manufacturing achievements

For the manufacturing and assembly of PCs, printers, and other information devices, we provide manufacturing contract services utilizing our long years of experience and achievements in this field.

In addition, we pursue benefits for our customers through the promotion of efficiency and equalization in our overall operations.

We have successfully completed numerous projects involving assembly and manufacturing contracts for medical equipment, nursing care equipment, and large printers/copy machines.

Building a Flexible Production Framework

-

-

Line manufacturingWith line manufacturing, which is well-suited to mass production, we are able to reduce overall costs through elimination of wasted fixed costs by securing manpower and improving manufacturing efficiency based on the customer's production schedule. We can also provide product inspection and repair services for defective items along with the manufacturing.

-

Cell manufacturingFor large products and small lots with a variety of products, we construct a cell manufacturing framework. In this way, we can improve skill levels through the deployment of dedicated staff members and shortening the time spent on each product. In addition, through comprehensive outsourcing services from stocking to manufacturing, we provide thorough handling for a variety of components, reducing the burden of inventory management and stocking for our customers.

-

On-site handlingIn cases where company regulations prohibit off-site outsourcing of operations, our staff can conduct consigned manufacturing operations on-site at customer manufacturing facilities. With our experienced staff deployed as team leaders, your project will achieve stable and efficient manufacturing performance as well as flexible handling for sudden changes in requirements.

-

Click here to make an inquiry.

Related Services

Quality control

Proxy inspection, examination

Proxy inspection, examination

Our on-site Japanese staff have abundant experience and will carry out examination work in China on your behalf.

After-care service

Kitting and maintenance support

Kitting and maintenance support

Providing one-stop service for maintenance and initial state restoration of PCs and other information system devices.